Targeted maintenance has become an often recited strategic goal in railway operator’s and maintenance provider’s roadmaps. With clear benefits, reaching from resource optimisation to higher performance and economic efficiency, reasons for adopting targeted maintenance are diverse. However, when it comes to practice, things can get difficult, as in many cases holistic, affordable and pragmatic approaches for these strategies are missing. Let’s find out why …

Starting from the beginning

For more than a decade, the railway industry has been undergoing an intense exercise of digitalisation. Be it in operations, management, or maintenance – like in other industries, data gathering, data-based analytics and data processing have popped up on agendas. And like in other industries, key questions are how to get the right data – and how to use it in a way that adds value to daily operations. That said, the idea of empowering a more data-driven approach in targeted maintenance has its challenges. Up to now, measurement trains and selective inspections have formed the base of taking a step or two in that direction.

But to bring this to the next level, a much broader database is needed. In an ideal scenario, this would be an area-wide monitoring tool that would provide data about changes in track health over an extended period. Furthermore, a smart solution must be implemented to read, process, and interpret this data to turn it into usable information. Finally, this information should be presented in a manner that is compatible with the processes of actual users, such as maintenance teams. The concept behind targeted maintenance revolves around these three cornerstones

But to bring this to the next level, a much broader database is needed. In an ideal scenario, this would be an area-wide monitoring tool that would provide data about changes in track health over an extended period. Furthermore, a smart solution must be implemented to read, process, and interpret this data to turn it into usable information. Finally, this information should be presented in a manner that is compatible with the processes of actual users, such as maintenance teams. The concept behind targeted maintenance revolves around these three cornerstones

One sensor to detect them all

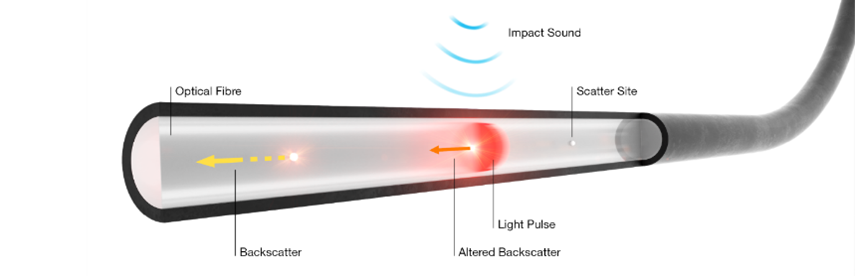

Following the structure described above, the first foundation we need is a possibility to monitor every meter of a track over wider areas. Ideally, on a 24/7 basis and with a sensitivity that allows to detect changes in track health. In fact, this sounds like a job for Fiber Optic Sensing – a relatively new technology in railways, but a very much proven one in other industries. From the family of Fiber Optic Sensing technologies, Distributed Acoustic Sensing (DAS) has turned out to be the most applicable one in a railway environment. The principle is quite simple: By connecting an existing single dark fiber of a standard fiber optic cable to a DAS-unit, this fiber will turn into a distributed acoustic sensor. Now, what is even more amazing than suddenly having a single sensor to monitor track health over 80 km at hand is: This sensor is capable of detecting all vibrations occurring along its length – such as those emitted by the interaction of a train wheel and the rail. This results in a visual vibrational signature created from the passage of each train over the whole track section monitored by the fiber. That said, we now have a digital twin of the vibrational patterns of each wheel-to-rail interaction on our track. Now, what’s next?

By means of Distributed Acoustic Sensing (DAS), single fibers of a fiber optic cable turn into a distributed acoustic sensor

Identify, locate, solve track defects

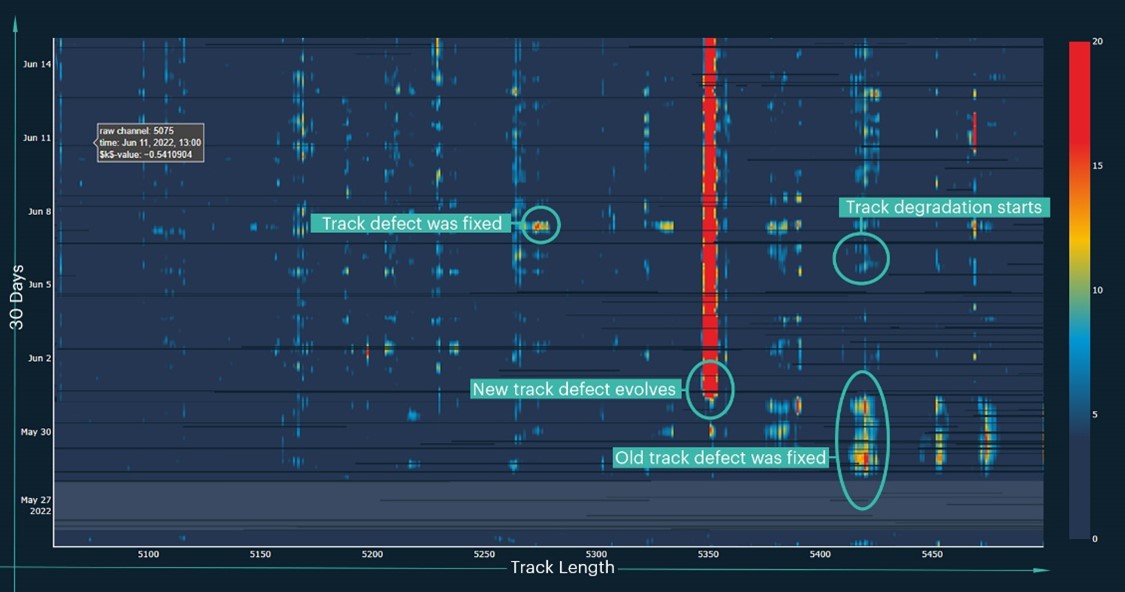

Using a sensor that records all vibrational patterns emitted by wheel-to-rail interactions over such a distance results in massive amounts of data. The true art of using digital twins is to extract relevant information from them after they have been created. This is best done by using smart algorithms. However, detections borne out of of vibrational changes from individual train passes might not be a reliable indicator for changes in track health – which is what we actually want to find as we’re aiming at supporting targeted maintenance. That said, we decided to not only look at the vibration patters at one location, but also add a dimension of time to the picture. Basically, we now get a full picture of a track, it’s vibrational behaviour under a train – and how this behaviour changes over time. From this, we create a heatmap that will indicate not only where changes are occurring, but also where they keep occurring and . Thus, the translation from data to actual information is completed. But now, what?

Are we inadvertently hinting at predictive maintenance here?

The Sonic Track Index (STI) summarizes vibrational changes that indicate track health changes over time

Providing information – speaking the same language

Seeing this information in a heatmap as presented in this image is quite insightful by itself. However, considering the three cornerstones described in the beginning of this article, the next step is to make this information actionable for existing processes. Time to have a look into true railway practice. Basically, there are many tools to investigate track health. As described earlier, all of these are proven technologies, but they do lack the dimension of continuity, that DAS adds to the game. However, the results gathered by established tools are usually provided in regular reports that give an overview of where condition has changed. Given the strength of a DAS-based system, this report can be provided anytime – ranging from weekly to monthly, whatever is desired. Thereby, the gaps in time between planned measurement cycles can be reduced. Changes can be detected, assessed and fixed right away if needed. Summarising this in a report similar to others means that for now no change in any process is needed.

In this picture, we see a battered rail joint as indicated by the vibration change hotspots of the heatmaps

Track Condition Monitoring empowers targeted maintenance

Sensonic's Track Condition Monitoring (TCM) Application operates according to the concept described in this article. It aids track maintainers in overcoming major challenges by facilitating targeted and preventive maintenance of track which helps with:

- Optimising track maintenance budgets

- Condition-based maintenance

- Assessing the efficacy of track maintenance and repair interventions

- Improved overall track health

- Higher operational safety and availability

Up to now, The Sensonic TCM Application has proven its value all over the globe. Harnessing the full potential of the latest DAS sensors, a broad range of changes in track health has been detected in various environments. Users have been able to interpret our reports to find condition changes corresponding with flaking rails, levelling defects, lateral wear, sleeper defects and many more. Responsible teams were informed via tailored reports. Based on this, actions were taken immediately where needed while further targeted maintenance tasks were planned accordingly.

Do you want to benefit from this solution as well and learn more about how it can be applied in your environment? Then get in touch to learn more about the Sensonic TCM Application now.