In this blog I look at what a flashover is, why flashovers are damaging to the overhead catenary system, why finding them is vital to run a reliable railway and how we can find them faster and more accurately using new detection techniques.

Electrified railways are more reliable than their fossil fuelled counterparts. However, when a fault occurs with the overhead catenary / overhead line equipment (OHLE), or in 3rd rail electrification, serious disruption and delays occur as rollingstock is stranded until the necessary repairs, inspection and re-energisation of the affected section are complete.

Dewirement of overhead catenary is one of the most serious types of incident from both safety, and traffic disruption viewpoints. Dewirement is where the overhead contact wire falls, or is pulled, down onto the train/track beneath. A dewirement above or in front of a train travelling at speed can lead to several kilometres of overhead catenary being damaged due to the long stopping distances of the train and the length of the tensioned catenary sections.

Repairs can take many hours or in some cases even days to complete.

Source: Trenvista - The independent magazine of the railway sector

What is an electrical flashover?

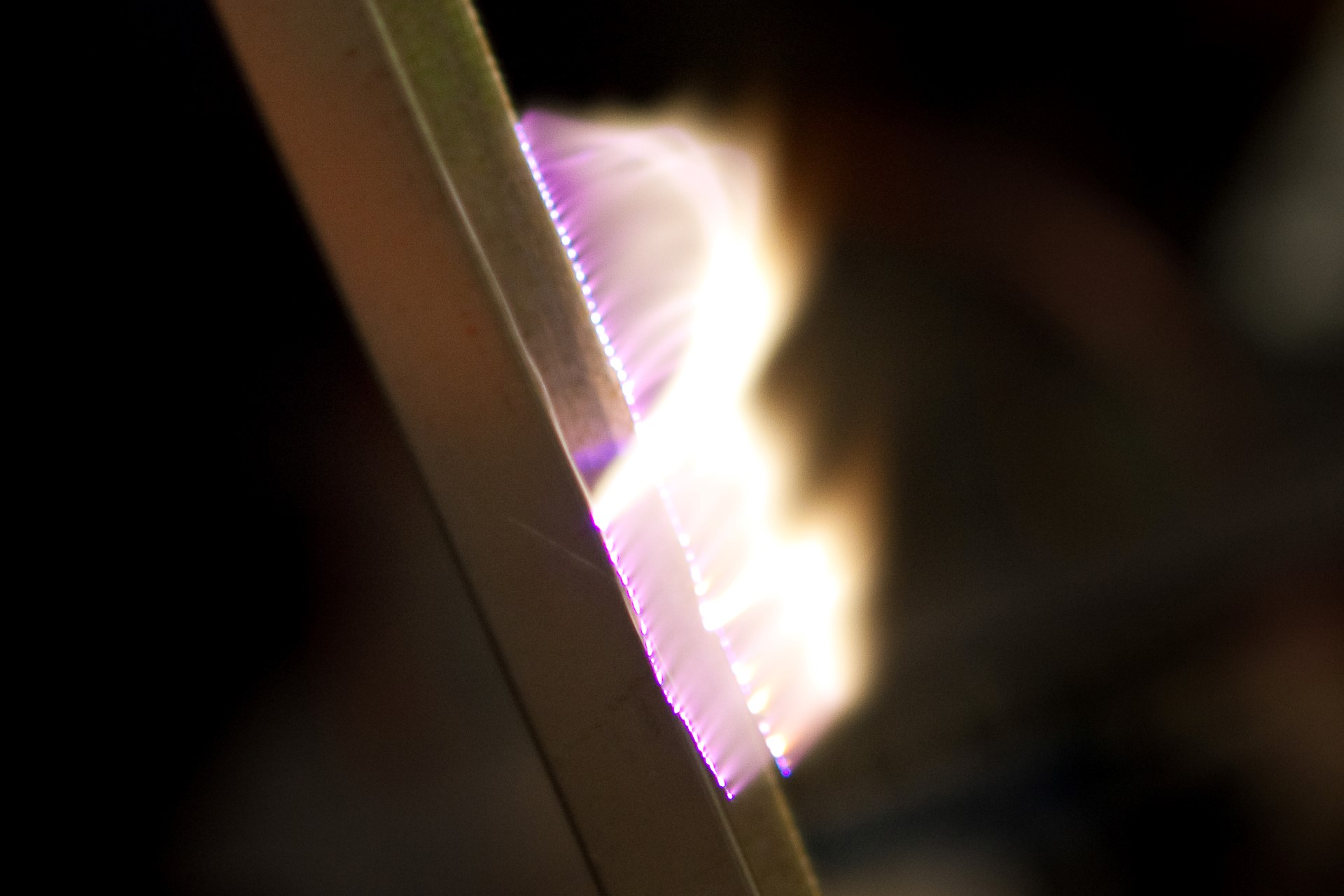

An electrical flashover is a high energy electrical discharge that occurs when an energized conductor comes into contact or close enough to another conductor to generate a spark. If this spark contains enough power to generate a plasma a flashover occurs. Plasma is a state of matter that is ionized, meaning that it has lost some or all its electrons. When a flashover occurs, the high-voltage discharge ionizes the air, creating a plasma. Plasma is a very good conductor of electricity and carries electrical current from the energized conductor typically to ground or another conductor.

Why is a flashover damaging to the catenary?

The plasma created by a flashover is extremely hot, reaching temperatures of several thousand degrees Celsius. This intense heat can cause damage to equipment, ignite fires and cause burns to nearby people. Where the flashover contacts components the intense heat can melt and cause material to be removed, weakening it, and causing failure.

Railway OHLE power supply systems have fault detection systems to cut the power when such issues occur, however they cannot act instantly so some material damage is inevitable where a flashover occurs. These damaged locations introduce potential weak points to catenary components which may lead to failure in the future reducing its long-term reliability.

In cases where a fault is not automatically detected, the components such as wires can be quickly melted through leading to a dewirement causing further significant infrastructure damage as well as the obvious safety implications of live conductors falling from overhead.

How do we find flashover faults and why is it important?

Conventionally identifying electrical flashover faults relies on manual visual inspection. If a section of catenary trips due to a fault, the section is inspected to find it. Depending on the equipment installed and procedure requirements a portion or sometimes even the entire section may require inspection. Using conventional power fault detection equipment, the fault location can be estimated to several hundred meters, in ideal conditions – often significantly more. Where this equipment is not fitted, if the entire section needs inspecting, which may be many kilometres in length, perhaps 20km, this takes considerable time and resources to achieve. If inspections are carried out at night, as is common, then the job becomes even more challenging with many inspections revealing “No fault found”.

Some faults like a fallen tree may be quite easy to spot. Smaller transient faults caused by birds or a foreign object contacting the catenary can be challenging, if not near impossible to find, as the evidence can be vapourised by the flashover event. Often the only signs are scorch marks on the structure or component.

It is important to pinpoint the location of the flashover to give inspections the best chance to find the source of the fault. The fault could be an issue likely to recur in future, or the damage caused by the flashover may lead to reliability issues in the future, e.g., arc damage to a wire leading to future wire break or dewirement.

There is now a better way to accurately locate flashover events, saving time, avoiding disruption, improving reliability, and increasing worker safety.

How can we find flashover faults faster and more reliably?

Flashover events are highly energetic, generating significant noise and vibration, for a hopefully very brief period. Sensonic utilises vibration sensing via fibre optics, to detect these vibrations and record them for analysis.

This allows Sensonic to remotely locate the flashover to within 10m before anyone needs to set foot onto the track.

This accurate location allows inspection and repairs teams to be dispatched directly to the incident site delivering multiple benefits:

- Improves response and recovery times

- Improves OHLE team productivity by reducing inspection times

- Improves safety by reducing time on track

- Improves future catenary reliability by finding faults that would often be missed

Want to know more about locating catenary flashovers? See our flashover location application pages or get in touch.

Contact us

What causes a catenary flashover?

Many factors can contribute to an electrical flashover, including:

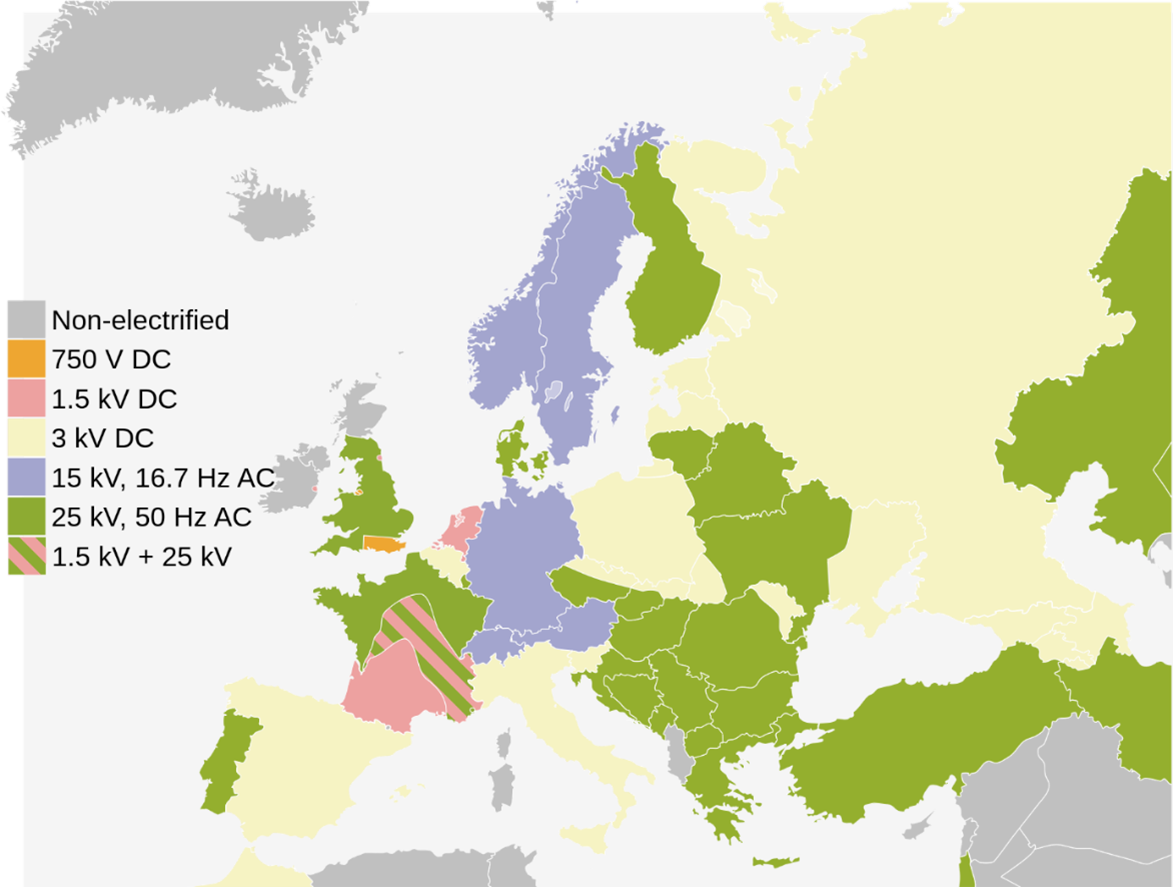

- High voltage: The higher the voltage, the more likely it is that an electrical flashover will occur. Railway electrification starts at 750V, and many catenary systems are energised with up to 25,000 Volts.

- Insulation: Insulation helps to prevent electrical current from flowing from one conductor to another. If insulation is damaged, it can increase the risk of an electrical flashover. As air is often used as an insulator, correct air gaps must be maintained.

- Contaminants: Contaminants, such as dirt, dust, or moisture, can weaken the insulation and increase the risk of an electrical flashover.

- Weather: High winds, rain, and snow can decrease air insulation gaps and decrease effectiveness of insulators. Hot temperatures or excess ice accumulation can cause the wires to sag.

- Foreign objects encountering the catenary, e.g., trees, birds or objects blown by the wind

- Damage to the catenary: Damage from collision or vandalism can degrade insulators or displace components decreasing air insulation gaps.

- Pantograph faults: Damaged units on trains can cause collision damage as above.

- Degradation of components: Over time, mechanical components can deteriorate, corrode or fatigue resulting in failure leading to an insufficient air/insulation gap.

- Vandalism or cable theft

The different electrification voltages across Europe

Europe rail electrification en - Railway electrification - Wikipedia

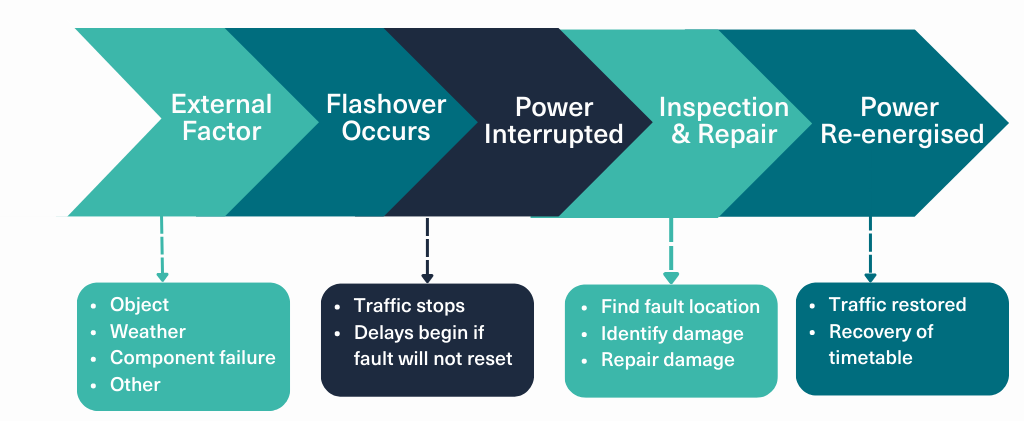

A typical flashover timeline

Different railways have different procedures and regulations around catenary traction power faults, however many have an inspection requirement, even if the original fault is only a temporary one. Inspection after a fault has occurred is vital to assess the damage caused and avoid future more serious events occurring in future. If inspection is not triggered or not carried out opportunity to improve the reliability of the catenary system is missed.

The inspection process can be significantly improved if the location of a flashover can be accurately determined. This both reduces the inspection time and allows a more thorough inspection of the suspect components to be carried out.

To find out more about how we can direct your teams straight to catenary flashover faults contact us.