In Spain, ADIF is responsible for administrating rail infrastructures, including tracks, stations, freight terminals and more. Genuinely, this implies track maintenance for which the company holds a division of highly specified experts – who became key users of the Sensonic Solution, harnessing the full potential of the Track Condition Monitoring (TCM) Application.

More requirements – less personnel

Like many other railway companies, ADIF is driving their business in a field of tension formed by increased railway traffic, accelerating maintenance requirements and a decreasing number of experts responsible for these areas. Thus, the company is always on the lookout for possibilities to make aspects of their operations more effective and cost efficient. When they joined forces with Sensonic, it was to integrate and verify the potential of Fibre Optic Sensing (FOS) as a brand-new technology in holistic railway asset condition monitoring. Results from substantial use and validation in real operation prove that the Sensonic Solution is a highly powerful tool for ongoing provision of insights about changes along the track, potentially caused by track wear and evolving track defects.

Early adopters became first movers

Today, ADIF are one of the first to benefit from actionable information that empowers them in implementing targeted maintenance strategies based on the TCM Application. Regular reports about changes in track infrastructure health empower ADIF’s maintenance team to optimize their maintenance processes and decrease their reaction time for preventive and corrective measures. Successful localisations of long-term rail degradations have supported ADIF in carrying out targeted maintenance tasks. This not only improves track health overall but additionally, available maintenance resources can be used more efficiently and coordinated. Whilst on top of this - unscheduled downtimes are reduced and overall safety is increased.

Findings in the field: proven value

After having introduced the concept on a 50 km track section with ADIF in October 2022, we have already identified 19 “locations of significant change” by end of the year, based on findings from the heatmap analysis, that were recommended for track inspection. 16 out of these locations showed considerable defects, that were classified between low and high in severity by ADIF’s track experts. Based on the information provided in the periodic Sonic Track Index Report, appropriate maintenance measures were initiated in a timely manner, making sure to prevent the track from more severe degradation and to keep operational downtimes as low as possible.

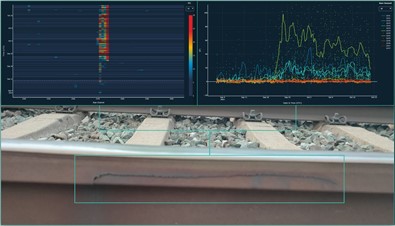

The picture shows a high-severity defect that was identified through TC heatmap analysis. It was a local levelling defect accompanied by a 20 cm fissure in the rail head. Temporary clamping followed by rail piece replacement of the affected section was initiated to prevent worse damage to be caused.

The picture shows a high-severity defect that was identified through TC heatmap analysis. It was a local levelling defect accompanied by a 20 cm fissure in the rail head. Temporary clamping followed by rail piece replacement of the affected section was initiated to prevent worse damage to be caused.  Rail replacement of affected section was initiated after first measures were taken based on insights from the Sonic Track Index Report

Rail replacement of affected section was initiated after first measures were taken based on insights from the Sonic Track Index Report

Switches set

With a strong conviction that FOS will not only become, but already is, an inevitable part of future-proof strategies to improve railway operations, ADIF has completed a validation phase of applying TCM and using it in practice. Results of this strengthened the confidence that improving maintenance by means of this ready-to-use application is another milestone in our common journey – which does not stop here, as there’s potential for optimisation of many more areas of railway operations using the Sensonic Solution.